Engineered for Industry

High-Performance Industrial Pumps

Reduce downtime and optimize performance with our robust industrial pumps, engineered to meet the high demands of your operations.

Equipment Failure Due to Harsh Conditions?

Let's Chat About Durable Pumps for Extreme Environments

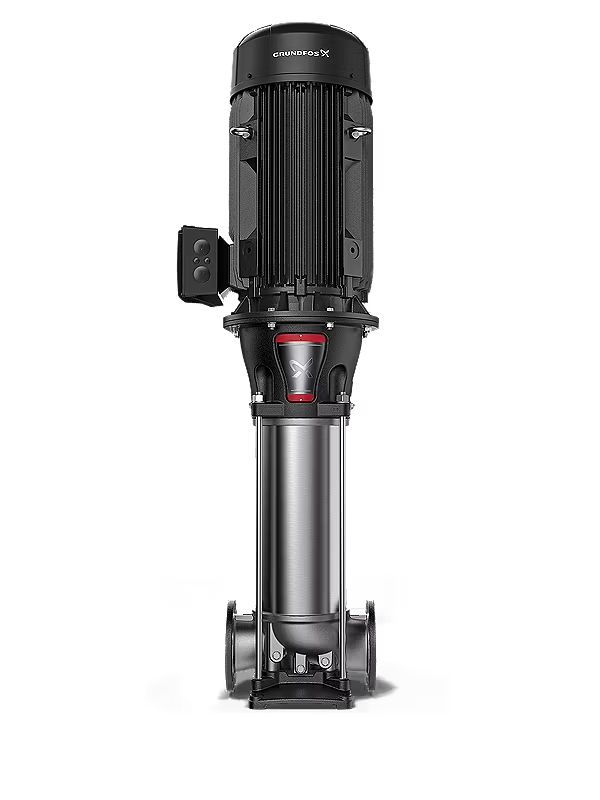

Industrial systems often face extreme conditions, from high pressure to abrasive chemicals. Our Grundfos CR pumps are built to handle tough applications, offering reliable performance even in the most demanding environments. With specialized shaft seals and durable materials, our pumps are designed to withstand long hours of operation with minimal maintenance.

High-efficiency motors for continuous operation

Corrosion-resistant materials for harsh environments

Long-term reliability with minimal downtime

Why Choose Ability Pump for Your Industrial Pump Needs?

Ability Pump Answers Your Top Questions

Selecting the right industrial pump for high-pressure applications involves assessing key factors such as the desired flow rate, total head requirements, and fluid characteristics (viscosity, abrasiveness, temperature, etc.). Pumps such as multi-stage centrifugal pumps or positive displacement pumps are often used for high-pressure systems, with the Grundfos CR and SP series being ideal choices due to their ability to handle high pressures efficiently.

Pump efficiency directly affects operational costs by determining how much energy is required to operate the pump. Higher efficiency reduces energy consumption, lowering operating costs and improving system performance. Variable-speed drives (VSDs) can also be integrated with industrial pumps to further optimize energy use by adjusting the pump speed to match system demand, reducing unnecessary energy expenditure.

Multi-stage centrifugal pumps are designed to provide high-pressure output and maintain consistent flow, making them ideal for industrial applications that require long-distance fluid transfer or high-lift systems. These pumps are particularly effective in water treatment, boiler feed, and irrigation systems where consistent and efficient operation is crucial. Their modular design also allows for customization to meet specific system demands.

The material of construction plays a critical role in the longevity, performance, and maintenance requirements of industrial pumps. Corrosion-resistant materials, such as stainless steel or titanium, are essential for applications dealing with abrasive fluids, chemicals, or seawater. For example, Grundfos SP pumps, made from stainless steel, are designed to withstand aggressive environments while ensuring high performance and minimal maintenance.

The required horsepower (HP) for an industrial pump is calculated based on the flow rate, total head, and system efficiency. The formula used is:

HP = (Flow Rate x Head x Specific Weight) / (3960 x Efficiency).

In high-demand systems, selecting the correct motor size is crucial for ensuring the pump runs efficiently without overloading the system. Our team can help evaluate your system and select the optimal pump size to meet your specific requirements.

When selecting a pump for abrasive fluids, it’s essential to consider factors like material durability, impeller design, and wear resistance. Pumps designed for abrasive fluids, such as the Grundfos CR series, are typically constructed from corrosion-resistant materials and feature wear-resistant impellers that minimize damage and increase lifespan. Additionally, the pump’s seals and suction capabilities must be designed to handle abrasive particles without clogging or reducing performance.

Cavitation occurs when vapor bubbles form in the pump due to insufficient suction pressure, leading to damage to the pump components. To prevent cavitation, ensure that the pump operates above the Net Positive Suction Head (NPSH) requirement and maintain proper suction pressure. Proper system design, such as avoiding sharp bends in suction lines and ensuring the pump inlet is properly sized, is critical for preventing cavitation and ensuring efficient pump operation.

To improve efficiency, it’s important to choose the right pump size and ensure it operates within its optimal performance range. Regular maintenance, energy-efficient pumps with variable-speed capabilities, and proper system design can also help reduce energy consumption and extend the life of your equipment. Our experts can assess your system and suggest improvements for better efficiency.

Positive displacement pumps are ideal for applications where a consistent, accurate flow is required, particularly with high-viscosity fluids or pumping at high pressures. These pumps move a fixed amount of fluid per cycle, regardless of the system pressure. Centrifugal pumps, on the other hand, are more commonly used in applications where high flow rates and low to medium pressures are needed. They are best suited for liquid transfer in water treatment, HVAC, and irrigation systems.

Signs that your industrial pump may need repairs or replacement include vibration, unusual noise, loss of pressure or flow, and increased energy consumption. If the pump is older and has already undergone several repairs, it may be more cost-effective to replace it with a newer, more energy-efficient model. Regular maintenance checks, including lubrication, seal inspections, and impeller checks, can help extend the pump’s life and reduce the need for premature replacement.

Have More Questions?

Reach Out to Our Team Today!

Request a Quote Today!

Our expert representatives at Ability Pump are ready to help you source the right product for your needs. Submit your request and we’ll provide a tailored quote and guide you through the selection process. Fill out the form below to get started!

Connect with the Pump Specialists

Our team is ready to support your operations with reliable solutions.

Contact us toll-free at:

1-800-263-5353