Inspect with Confidence Using Our Well Cameras & Pipe Reels

Efficiently locate blockages, damage, and issues within your well system with our high-quality camera and pipe reel solutions designed for durability and accuracy.

Limited Visibility for Well Inspections?

We Offer Well Camera Systems for Detailed Inspections

Traditional inspection methods can provide limited insight into the condition of water wells, making it hard to identify issues like clogged pipes or structural damage. The R-CAM 1000 portable well camera system provides high-resolution video profiles of the well’s interior, offering both downhole and side-view scanning for comprehensive inspections. Its 360-degree rotation allows you to get a complete picture of the well’s condition, helping you identify problems early and prevent costly repairs.

Dual-view video: Downhole and side-view scanning for full inspection coverage

High-definition resolution for clear, accurate results

Waterproof to 500 PSI for reliable use in demanding conditions

Portable and easy to use with an integrated lighting system and protective case

Experiencing Difficulty and Risk While Manual Pump Pulling?

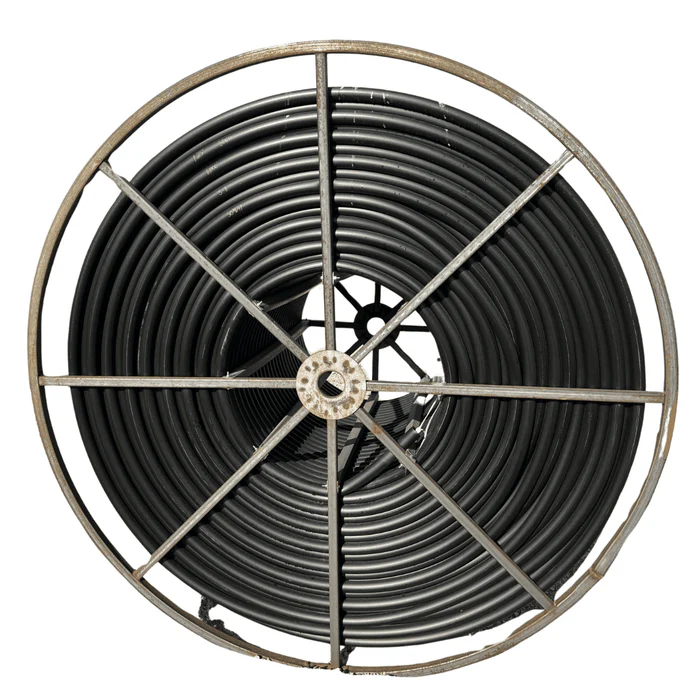

Explore Poly Pipe Reelers for Safe, Efficient Pump Pulling

Pulling pumps manually can be dangerous and time-consuming, often leading to back injuries and extended downtime. Our Poly Pipe Reeler provides a safer, faster way to pull pumps from wells without laying the pipe on the ground, keeping the process sanitary and reducing the risk of damage to the pipe. With the ability to pull up to 1,200 lbs at 40-45 ft/min, the Poly Pipe Reeler significantly reduces labor and improves safety, allowing one person to do the work of three.

Faster and safer than manual methods

Prevents pipe damage and minimizes downtime

Hydraulic, AC, or DC-powered for versatility

Lightweight polyethylene drum for easy handling and durability

Limited Access to Well Tools and Parts?

We Have Comprehensive Well Equipment for Every Need

When it comes to well maintenance, having the right tools is essential for effective repairs and inspections. We offer a variety of well equipment, including well casing brushes, check valves, well points, and drive shoes to ensure your system stays in top condition. Whether you need to remove mineral debris from well casings or service your pump, our Maass Midwest accessories provide high-quality, durable solutions for every task.

Well casing brushes for cleaning mineral or bacterial debris

Well service tools for efficient repairs and maintenance

Customizable pitless adapters for specific well requirements

Why Choose Ability Pump for Your Well Parts Needs?

Ability Pump Answers Your Top Questions

When selecting a well camera system, it’s essential to match the camera’s diameter and length with the size of the well. For shallow wells with smaller diameters (3″-6″), a compact camera like the R-Cam 1000 works well, offering flexibility and high-definition imaging. For deeper wells or larger diameters (up to 12″), ensure that the camera system, such as those equipped with 360-degree rotating side views, can provide clear images at greater depths and allow for comprehensive inspections. Always consider the pressure rating of the camera to ensure it can handle the conditions at your well’s depth.

The R-Cam 1000 provides a significant improvement over traditional inspection methods, such as visual inspection with a flashlight or manual depth measurements. Equipped with high-resolution video imaging and 360-degree rotation, the R-Cam allows for more detailed, reliable, and efficient inspections, reducing the need for costly and time-consuming physical well evaluations. It provides real-time feedback with a clear video profile, making it ideal for identifying issues like clogs, structural damage, or mineral deposits with high accuracy.

To prevent cable wear and extend the life of your camera system, it’s important to ensure proper cable management during use. When deploying the camera, make sure the cable is not under tension and is properly coiled after use. For systems like the R-Cam 1000, a Kevlar-reinforced cable is designed for durability, but avoiding excessive pulling or twisting will help reduce the risk of abrasion. Regularly inspect the cable for signs of wear and replace it if necessary to maintain inspection quality.

Pump pullers significantly reduce labor and improve safety by eliminating the need for manual pump removal, which can lead to back injuries and downtime. The Poly Pipe Reeler is an efficient tool that allows for the safe and sanitary retrieval of submersible pumps without the need to lay piping on the ground. Using a hydraulic-powered or electric-powered reel allows a single operator to safely remove and replace pumps with minimal risk, significantly reducing time and effort.

Polyethylene offers several advantages over steel, including lightweight, corrosion resistance, and durability. Unlike steel, polyethylene does not rust, and it is less prone to denting or damage from harsh environments. Polyethylene pump pullers, like the Poly Pipe Reeler, offer a strong, reliable solution that’s easier to handle and transport, making them more efficient in field operations. The non-corrosive nature of polyethylene ensures that the equipment lasts longer and maintains high performance.

The choice of pump puller depends on the diameter of the pump, the depth of the well, and the material of the pipe. Poly Pipe Reelers are available in various sizes (e.g., 16-inch and 24-inch drums) to accommodate different pipe sizes. Ensure that the reel’s pulling capacity is sufficient for the pump’s weight and the depth of the well. It is also important to consider the power options (electric, hydraulic, or DC-powered) based on the available power sources and the scale of the pumping system.

When selecting water well equipment, you need to consider quality, durability, and the specific needs of your system. For example, high-quality check valves, well points, and pumping cylinders are critical for ensuring the system’s long-term reliability. Equipment made from stainless steel or corrosion-resistant materials is essential for harsh conditions, and choosing multi-functional tools that can be used across different well systems can save both time and cost in maintenance activities.

Effective well camera systems for deep wells should have features such as high-resolution imaging, 360-degree rotation, pressure tolerance, and long cable length (up to 1,000 feet). For deep well inspections, a camera system must be able to provide clear video profiles under high-pressure conditions while remaining durable enough to withstand frequent use. Additionally, a high-intensity LED lighting system is crucial for ensuring visibility at depths with minimal ambient light.

The durability of well equipment significantly impacts cost-effectiveness. Higher-quality equipment made from corrosion-resistant materials like stainless steel or polyethylene will last longer, reducing the need for frequent replacements. While the initial investment may be higher, the long-term savings in maintenance costs, downtime, and repairs make durable equipment a more cost-effective solution for water well service providers.

Well inspection cameras are crucial tools for preventive maintenance by providing real-time visibility into the condition of the well casing, pipes, and pump components. By performing regular camera inspections, you can identify issues like clogs, mineral deposits, and structural damage early on, before they lead to major failures. This proactive approach not only helps to maintain optimal system performance but also extends the lifespan of the equipment, reducing the need for costly repairs and system replacements.

Have More Questions?

Reach Out to Our Team Today!

Request a Quote!

Submit your request today, and our expert team at Ability Pump will get back to you quickly with a tailored solution to meet your needs.

Fill out the form below to get started!

Connect with the Pump Specialists

Our team is ready to support your operations with reliable solutions.

Contact us toll-free at:

1-800-263-5353